oh for the love of Red…

Everybody has ’em. Most probably deny ’em. But I’ve noticed, walking with people in the city, almost no one steps on a crack.

Almost no one walks under a ladder (at least without thinking twice).

Mine are of another type, peculiar to living Urban Style. You probably share some of them.

Yes, I always wink at the big black cat that is perpetually lounging in my front yard. I do not know Senor Gato, but I smile at him – with a grin on the outside that almost matches the huge grin on the inside as I chuckle and think I’ve made some kind of cosmic bank deposit I’ll be withdrawing later when I need it.

Yes, whether walking or riding anywhere in the Windy City, if I happen to pass under the El tracks, I make a wish. If the train is particularly LOUD, I make two. Always. And if you are with me, you must wish along (or at least pretend to – and if crunched-up closed eyes are any indication, most do…)

Yes, when one of the top 3 superstitions in my urban list appeared in front of my Jeep, I lunged. I’d scored a Parking Place Right In Front of The Building I Wanted to Visit! In a Loading Zone – where the tariff for 15 minutes of doing business in the art supply store was mere flashing hazard lights.

But wait – this Parking Superstition is two-pronged; not only do I get to enjoy a pass from the parking pirates (up to $33.00 to park anywhere near downtown) BUT the Easy Empty Space is a clear indicator that I’m Supposed to be where I am! SHOPPING!

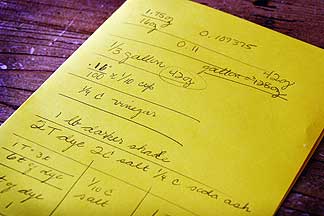

And this is no regular shopping – I am on the Hunt for Dye Stuff. Tomato Red Dye. This is the catalyst that will transform some peculiarly tepid lavender yarn I have that is calling out to be something else. I am, but of course, in thrall.

I must grab the dye, quickly return to the hut, and stir. When I jump in the car, and hear a click-click-click, I cannot believe my ears – and my hand goes into the pocket of my coat. Finding no cell phone, I know I’m hosed – I’d run down to the store, no purse, no cards, and am now left holding just a bagful of dye.

So, taking strength from the Brown Line Tracks almost overhead, I do what any sane person would do – I beg for a jump start. 3 tries later, no one with cables can be found (although all were willing). I move on to an Illinois Highway Dept. Truck driver (they almost always have cables). He snorts and tells me to call 311. Indeed!

An icy rain propels me into my pocket where I finger a Twenty Dollar Bill and start waving down cabs. 3 tries later, I am jumpless (although all were Very Willing).

Desperate now, looking like a drowned rat, I pull all my luck to me and promise Never Again will I leave the house to run to the store wearing only what looks like pajamas topped off with my infamous Midnight Cowboy cordouroy jacket, and I start on my last helper class of fellow drivers – the Delivery Man.

One try and a double sawbuck later, with his cousin’s cables thrown in for good measure, my car is revived and I am enjoying the most wonderful Superstition of All: the Good Neighbor in the Big City! KAching…